Error: Contact form not found.

Ghee Clarification

Ghee Clarification

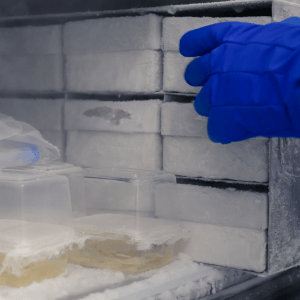

A ghee clarifier machine is a specialized piece of dairy processing equipment designed to purify and polish ghee (clarified butter) by efficiently separating out impurities, milk solids, and water remnants. These machines play a vital role in modern ghee production, helping manufacturers deliver a high-quality product that meets both domestic and export standards while reducing waste and ensuring process efficiency. Below is an in‐depth look into the technology, working principles, key specifications, and market options available for ghee clarifier machines.

- Capacity : 250 TO 1000 LTR

Working Principle and Design

Centrifugal Separation

The core mechanism behind a ghee clarifier machine is centrifugal separation. Ghee is fed into a bowl or separator where, under high-speed rotation (achieved via a motor-driven disc system), centrifugal force pushes impurities and milk solids to the outer edges. The clarified ghee collects at the center or through a specifically designed outlet. This separation is enhanced further by a temperature-controlled environment where the ghee is maintained at an optimal range—often between 75°C and 90°C—to reduce its viscosity and improve separation efficiency.

Disc and Bowl Configuration

Many of these machines use multiple stainless steel (S.S.) discs housed inside a solid wall bowl. The high number of discs (for example, some models use up to 52 discs) increases the surface area and improves the resolution of the separation process. The bowl is typically constructed from high-grade stainless steel (commonly S.S. 304) to ensure durability, corrosion resistance, and ease of cleaning.

Integrated Heating and Control Systems

Besides separation, ghee clarifier machines incorporate integrated heaters or hot water circulation systems to maintain the required operating temperature. Some designs use hydraulic systems with specific flow rates (e.g., 1000 LPH hydraulic capacity) and are equipped with electric motors (commonly in the range of 0.75–1 HP) configured for optimal performance under varying loads.

Technical Specifications

Manufacturers offer a range of models catering to different production scales. For instance, one model from an established manufacturer is characterized by the following features:

Options like 1000 LPH (liters per hour), and variants capable of processing up to 3000 LPH.

Typically featuring a 1 HP, 0.75 kW three-phase motor running at 1425 RPM.

Models may include 34 to 52 discs, which assists in effective separation.

Operative temperature is kept between 75°C and 90°C.

Use of S.S. 304 for both the bowl and spout sets ensures longevity and food-grade safety.

These specifications not only illustrate the mechanical robustness but also highlight how these machines are designed for efficiency and precision in ghee clarification, contributing to both consistent product quality and reduced manual labor.

Benefits of Using a Ghee Clarifier Machine

Enhanced Product Quality

The efficient separation of milk solids and water improves the purity and shelf life of the ghee.

Increased Efficiency

Automation reduces the time and labor associated with traditional manual clarification methods.

Waste Reduction

By reclaiming ghee from residues, manufacturers can optimize yields and improve profitability.

Sustainable Operation

Modern clarifiers often feature user-friendly interfaces and control systems that contribute to consistent, high-quality production while maintaining safety and hygiene standards.