The demand for premium and affordable ice cream continues to grow in India, making it the perfect time for businesses to invest in a modern Ice Cream Plant. Whether you are a startup, an established dairy company, or expanding a food processing unit, choosing the right plant setup can significantly improve product quality, production efficiency, and long-term profitability.

This complete guide explains everything about ice cream plants from machinery and production processes to choosing the right manufacturer

⭐ What Is an Ice Cream Plant?

An Ice Cream Plant is a fully integrated setup of machinery used for preparing, pasteurizing, homogenizing, freezing, and packaging ice cream on a commercial scale. These plants are designed to ensure:

- Creamy & consistent texture

- Perfect overrun and mixing

- Hygienic production

- Rapid freezing for better taste

- Long shelf life and product stability

⭐ Types of Ice Cream Plants

Depending on your production capacity and business goals, ice cream plants come in different configurations:

1. Small-Scale Ice Cream Plant

Ideal for startups, local brands, and cloud ice cream kitchens.

Capacity: 50 LPH – 200 LPH

2. Medium-Scale Ice Cream Plant

Suitable for growing brands or regional manufacturers.

Capacity: 200 LPH – 1000 LPH

3. Large-Scale Ice Cream Plant

Fully automated, high-capacity systems used by major dairy and FMCG companies.

Capacity: 1000 LPH – 5000+ LPH

⭐ Key Machinery Used in an Ice Cream Plant

A well-designed plant includes the following equipment:

1. Mixing & Blending System

Combines milk, cream, sugar, stabilizers, and flavors.

2. Pasteurization Unit

Heats the mix to destroy harmful microorganisms and ensure safety.

3. Homogenizer

Breaks down fat molecules to give a smooth, creamy texture.

4. Aging Tank

Stores the mix at low temperature to enhance flavor and stability.

5. Continuous Ice Cream Freezer

Freezes the mix while incorporating air for perfect overrun.

6. Filling & Packaging Machine

Used for cups, cones, tubs, and bulk packages.

7. Hardening Tunnel / Blast Freezer

Rapid-freezes ice cream to lock in texture and shape.

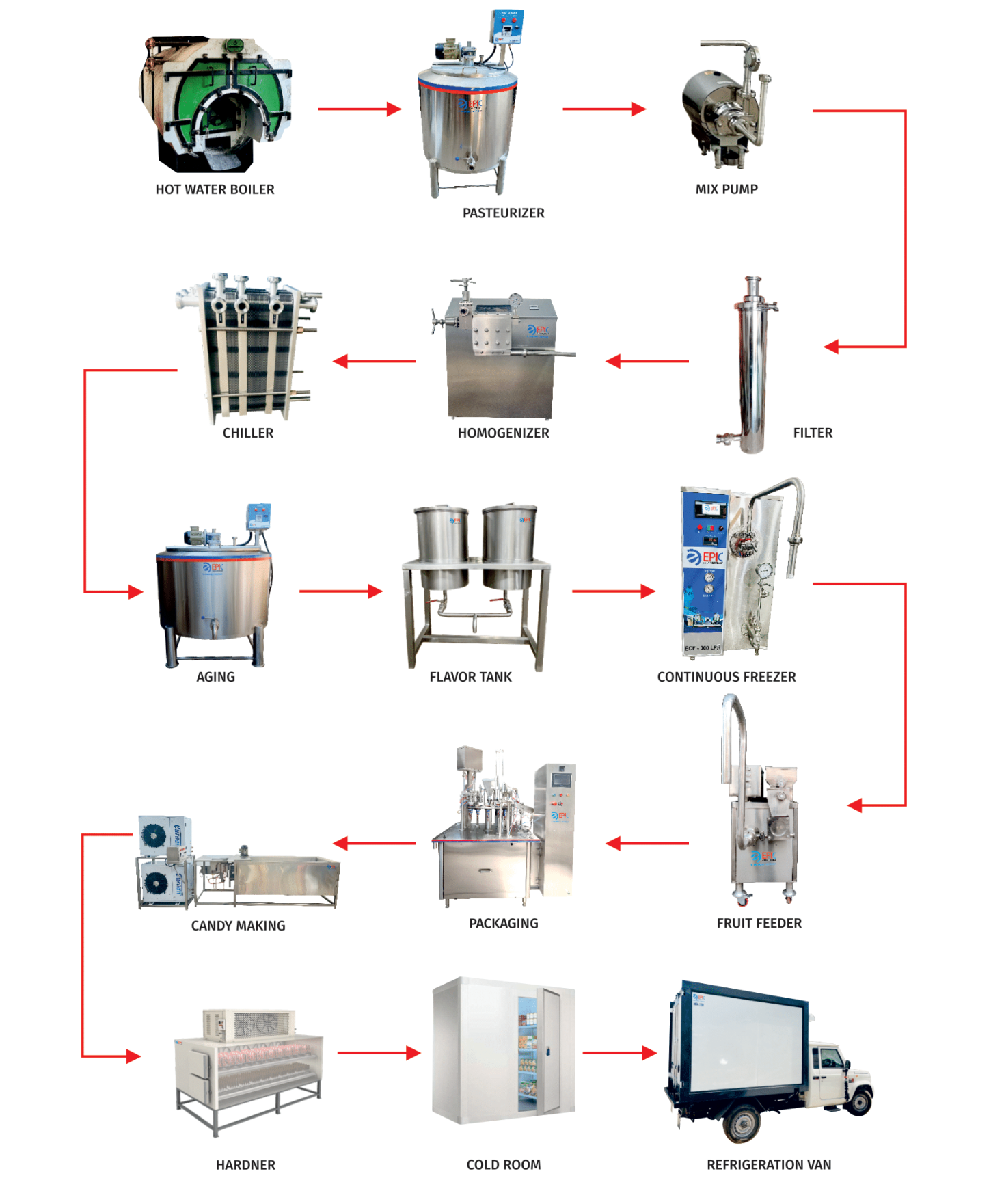

⭐ Step-by-Step Ice Cream Manufacturing Process

Here is a simplified flow of production:

- Mix Preparation

- Pasteurization

- Homogenization

- Aging

- Flavor Mixing

- Freezing (Continuous Freezer)

- Filling & Packaging

- Hardening & Storage

A good plant ensures each step maintains hygiene, temperature control, and consistency.

⭐ How to Choose the Best Ice Cream Plant Manufacturer in India

When selecting the right manufacturer, consider the following:

✔ 1. Quality of Machinery

Look for food-grade stainless steel, automation, durability, and energy-efficient refrigeration.

✔ 2. Customization Options

Every business has different capacity needs, choose a manufacturer that offers tailor-made solutions.

✔ 3. After-Sales Support

Installation, operator training, maintenance, and spare parts availability are essential.

✔ 4. Industry Expertise

Choose a company with experience in dairy equipment and ice cream processing.

✔ 5. Technology & Innovation

Modern plants offer PLC control panels, automated valves, improved cooling systems, and consistent output.

⭐ Epic Dairy Technology – A Trusted Name for Ice Cream Plants

Epic Dairy Technology is known for delivering high-performance, reliable, and customizable Ice Cream Plant solutions across India. Our plants are designed to meet both small-scale and industrial production needs while ensuring:

- Superior product quality

- Energy-efficient operations

- Better hygiene & food safety

- Long-term durability

- Complete technical support

Whether you need a compact plant or a fully automatic line, we offer complete solutions tailored to your budget and production goals.

⭐ Cost of Setting Up an Ice Cream Plant in India

The investment depends on plant size, machinery, automation level, and brand requirements.

Factors affecting cost:

- Capacity

- Type of freezer

- Automation level

- Packaging requirement

- Cold storage & hardening need

⭐ Why Ice Cream Plants Are a Profitable Investment

- India is one of the fastest-growing ice cream markets.

- Demand peaks in summer but continues year-round.

- High-margin products.

- Easy to diversify (cones, sundaes, stick ice cream, kulfi, soft serve, etc.).

- Easy to scale production with add-on modules.

⭐ Conclusion

A modern Ice Cream Plant plays a crucial role in ensuring delicious taste, smooth texture, hygiene, and production efficiency. With the right equipment and a reliable manufacturer like Epic Dairy Technology, businesses can achieve high-quality output and long-term success in the competitive ice cream industry.

FAQs

1. What capacity of ice cream plant should I choose?

Choose based on your business size — small (50–200 LPH), medium (200–1000 LPH), or large (1000+ LPH).

2. What is the lifespan of ice cream plant machinery?

High-quality stainless steel machinery typically lasts 10–15 years with proper maintenance.

3. Do manufacturers provide installation and training?

Yes. Reputed manufacturers like provide installation, operator training, and after-sales service.

4. How much space is required for an ice cream plant?

A small plant may need 500–800 sq ft, while larger plants require more based on capacity.

5. Can I customize my ice cream plant?

Yes, Epic Dairy Technology offers fully customizable setups based on capacity, automation, and product type.